Green Chemistry Campus in Bergen op Zoom

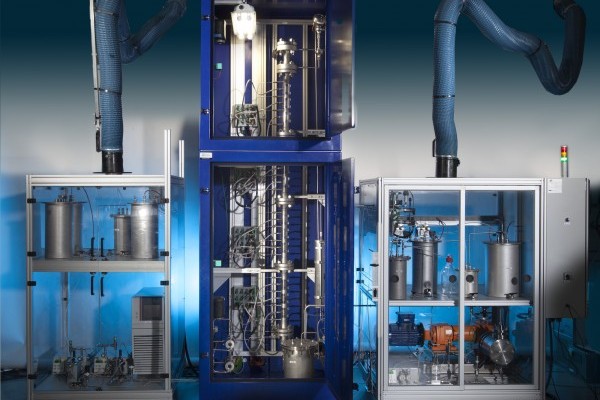

Continuous Biphasic Reactor Skid

This skid enables the conversion of biomass-derived sugar streams into the platform chemical Furfural, 5-hydroxymethylfurfural (HMF) and levulinic acid on the multikilogram per day scale (skid throughput of 1-10kg/hr). Please explore this skid via the Virtual Reality model of Biorizon’s biomass to bio-aromatics lab at the Green Chemistry Campus in Bergen op Zoom!

Biorizon’s biomass to bio-aromatics lab

Biorizon co-initiator TNO has got the following equipment in its biomass to bio-aromatics lab.

- Biphasic Reactor (BPR): Designed for the continuous conversion (1-10 L/h) of lignocellulosic sugar solutions to furanic intermediates.

- Multi-Purpose Batch Reactor (MPBR): Flexible reactor setup, with an integrated filtration unit, to prepare a variety of bio-aromatic samples.

- Condensation Skid: Continuous reactor (1-10 L/h) for corrosive reactions. Mainly used to prepare furanic intermediates.

- Continuous Flow Diels-Alder Skid: Continuous reactor (1-10 L/h) for bio-aromatics/precursor production on multi-kilogram per day scale. More info on this skid, can be found here.

Interested to test samples of bio-aromatics in your applications?

Earlier, Biorizon sent out a call for participation to attract companies that are willing to test samples in their applications. Several companies from all over Europe have responded to this call and Biorizon is currently discussing the results with these companies.

If you are interested in testing samples of bio-aromatics in your applications, discussing the desired characteristics and sharing the results with Shared Research Center Biorizon, please contact Roger Blokland via roger.blokland@tno.nl of +31 (0)6 11 27 60 55.

Acknowledgements

- The Biphasic Reactor and the Condensation Skid were realized within the SCeLiO4B project, that is established by a contribution of the European Regional Development Fund, OPZUID, the Dutch ministry of Economic Affairs and the Dutch provinces of Noord-Brabant and Limburg.

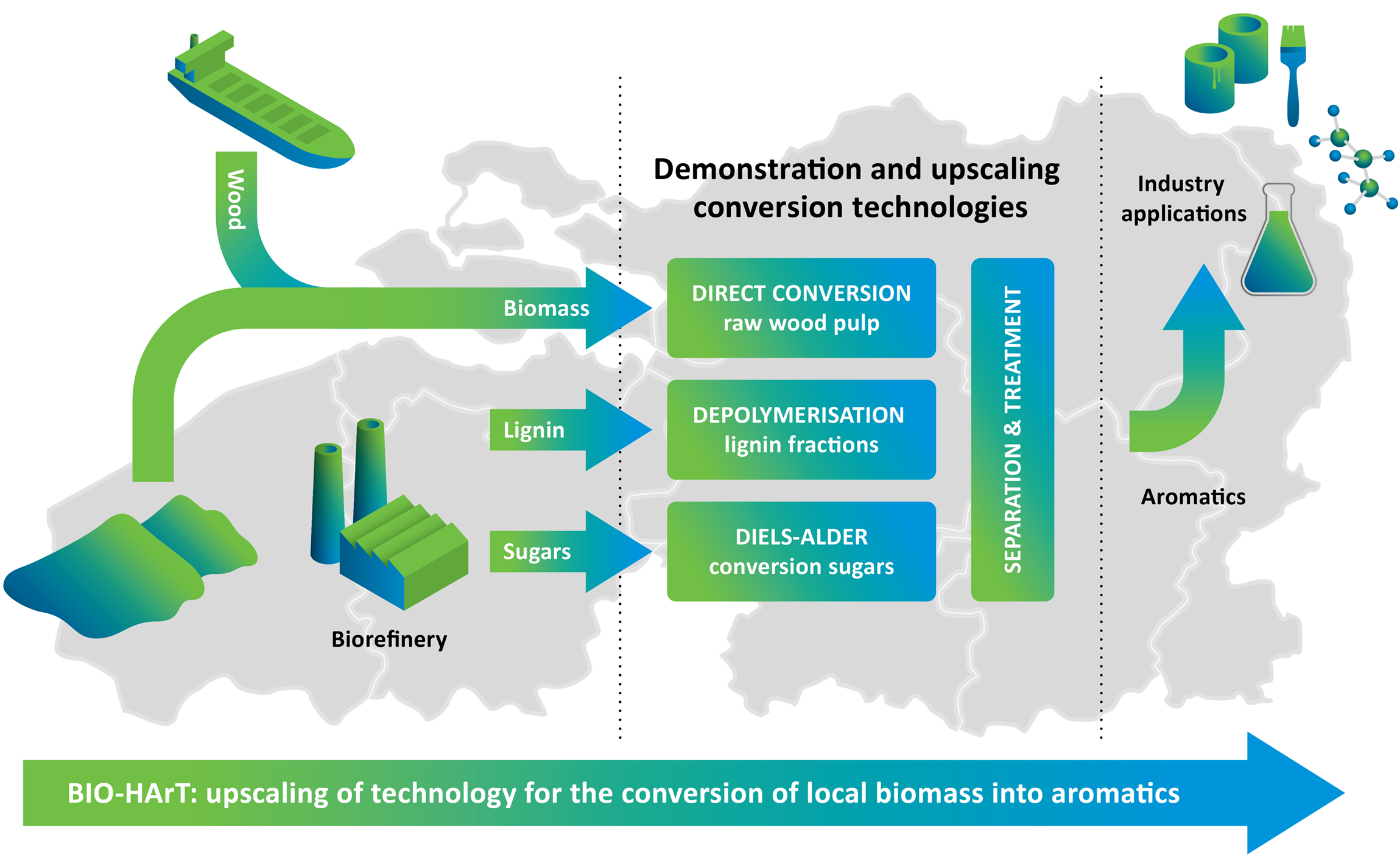

- The Continuous Flow Diels-Alder Skid was realized within the BIO-HArT project, that is established by a contribution of the European Interreg V Flanders-The Netherlands program that stimulates innovation, sustainable energy, a healthy environment and the labor market by means of cross-border projects.