News

17-10-2017

Biorizon presents virtual reality model of demonstrator for bio-aromatics

Biorizon presents a virtual reality model of it's Continuous Flow Diels-Alder Skid. You can easily walk through the skid and by clicking on the hot spots you get more detailed information. A unique experience! At Biorizon's Annual Event, on 30 November in Antwerp, participants got the opportunity to undergo the full virtual reality experience by wearing special goggles.

Virtual Reality Model of Biorizon's Continuous Flow Diels-Alder Skid

Video of Biorizon's Continuous Flow Diels-Alder Skid

Biorizon's Continuous Flow Diels-Alder Skid enables production of bio-aromatics samples (or precursors thereof) on the multikilogram per day scale (skid throughput of 1-10kg/hr). This demonstrator is highly flexible - feed chemicals, reactor configuration, and process parameters can all be broadly altered, enabling access to a vast array of bio-aromatics (and their precursors). In this way Biorizon will fulfill the desires of industry with respect to supplying the first kilogram scale samples for application testing. The unit will furthermore be utilized to better understand and optimize processes, leading to the construction of the first pilot plant in 2020 (~40 ton/annum production) and the first commercial production facility in 2025 (>5 kton/annum production).

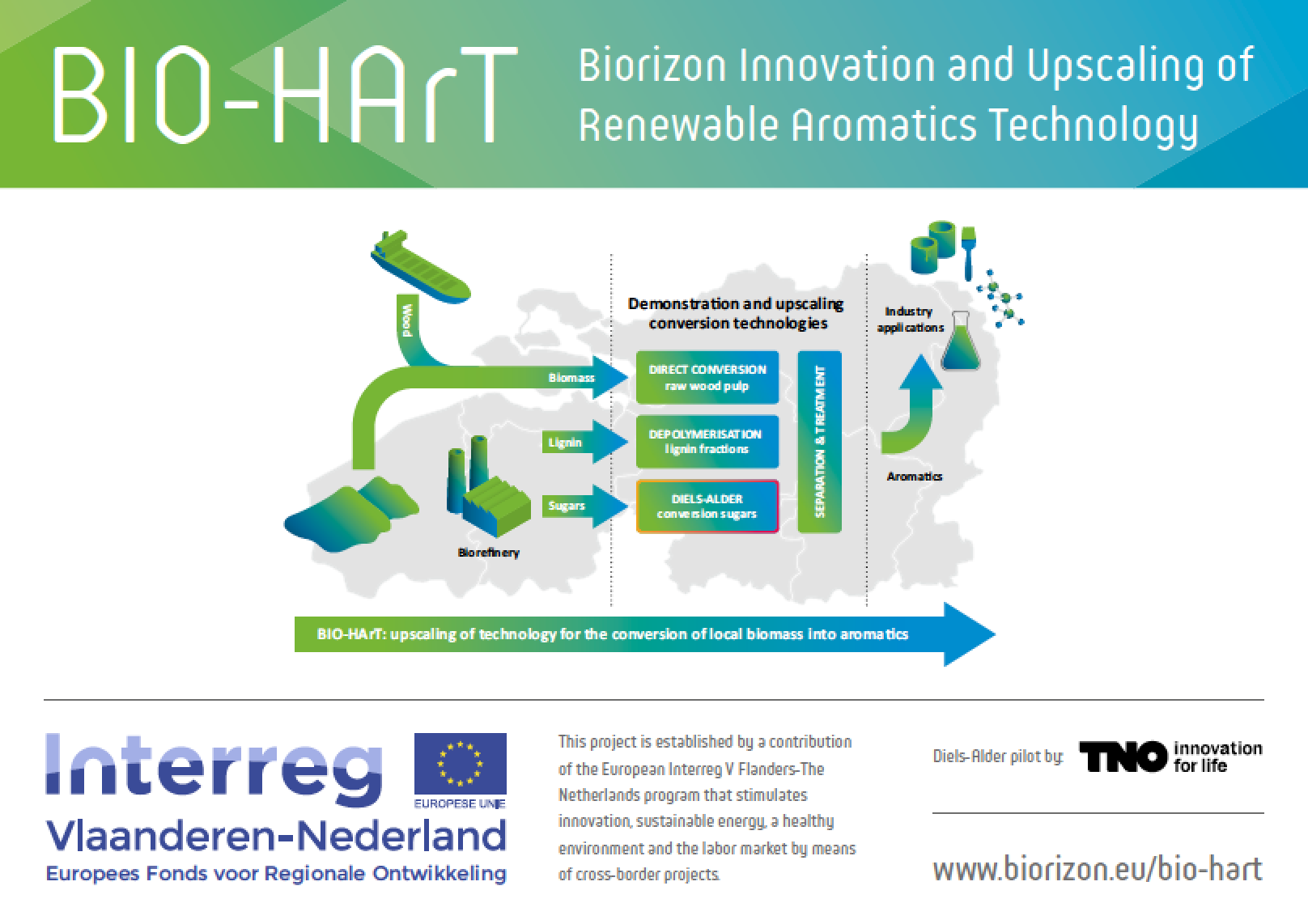

Biorizon Innovation and Upscaling of Renewable Aromatics Technology

The realization of this demonstrator is another important milestone within the ‘carbohydrates to aromatics route’ in the BIO-HArT project. It was custom built for Biorizon by Zeton based on a unique design by TNO. It can process many different feed chemicals, giving access to a wide range of bio-aromatic products. This demonstrator enables Biorizon to produce samples of bio-aromatics in larger quantities, and more efficiently, than before, fulfilling the requests from companies for chemicals with specific functionalities on a multi-kg scale.

By scaling up the Diels Alder chemistry from lab- to pilot-scale (throughput: 1-10kg/hr) Biorizon will be able to optimize two different routes to bio-aromatics, and thus prove the industrial feasibility of the processes.

“Coming up with a design ‘in steel’ that could operate the desired processes, and be realized within the timeframe and budget of the project, was challenge in itself”, BIO-HArT project manager Nadine Wennersbusch explains.

Testing the most economical route to match companies’ requirements

Besides the realization of the demonstrator itself, the goal of the BIO-HArT project is to further optimize the processes for the production of bio-aromatics. Different parameters, such as reactant feed flow rates and ratios as well as reaction pressure and temperatures, can influence the efficiency of the reaction. All these parameters, amongst others, can be varied in the set-ups to determine the optimal settings for the highest yield and selectivity. These results can then be used to evaluate the technical and economic feasibility of the process at industrial scale.

Interested to test samples of bio-aromatics in your applications?

Earlier this year, Biorizon sent out a call for participation to attract companies that are willing to test samples in their applications. Several companies from all over Europe have responded to this call, and with the realization of the demonstrator, Biorizon is expecting to discuss the results with these companies by the first quarter of 2018.

If you are interested in testing samples of bio-aromatics in your applications, discussing the desired characteristics and sharing the results with Shared Research Center Biorizon, please contact Monique Wekking via monique.wekking@tno.nl or +31 (0)6 46 84 73 58.

Profitable and sustainable prospects for the chemical industry

Aromatics are one of the main raw materials used by the chemical industry: 40% of all chemicals are aromatic by nature. Aromatics are currently isolated from fossil sources, which leads to the emission of CO2. Shared Research Center Biorizon, initiated by TNO, VITO, ECN and Green Chemistry Campus, develops, together with partners, technologies to produce aromatics from plant residues. This reduces dependency on oil, leads to lower CO2-emissions, and provides profitable and sustainable prospects for the chemical industry and its suppliers.

Interreg

The BIO-HArT project is established by a contribution of the European Interreg V Flanders-The Netherlands program that stimulates innovation, sustainable energy, a healthy environment and the labor market by means of cross-border projects.

Photo: Diels-Alder pilot by TNO