Participation Calls

24-09-2020 - 31-12-2020

Biorizon invites manufacturers to test bio-aromatics with premium properties

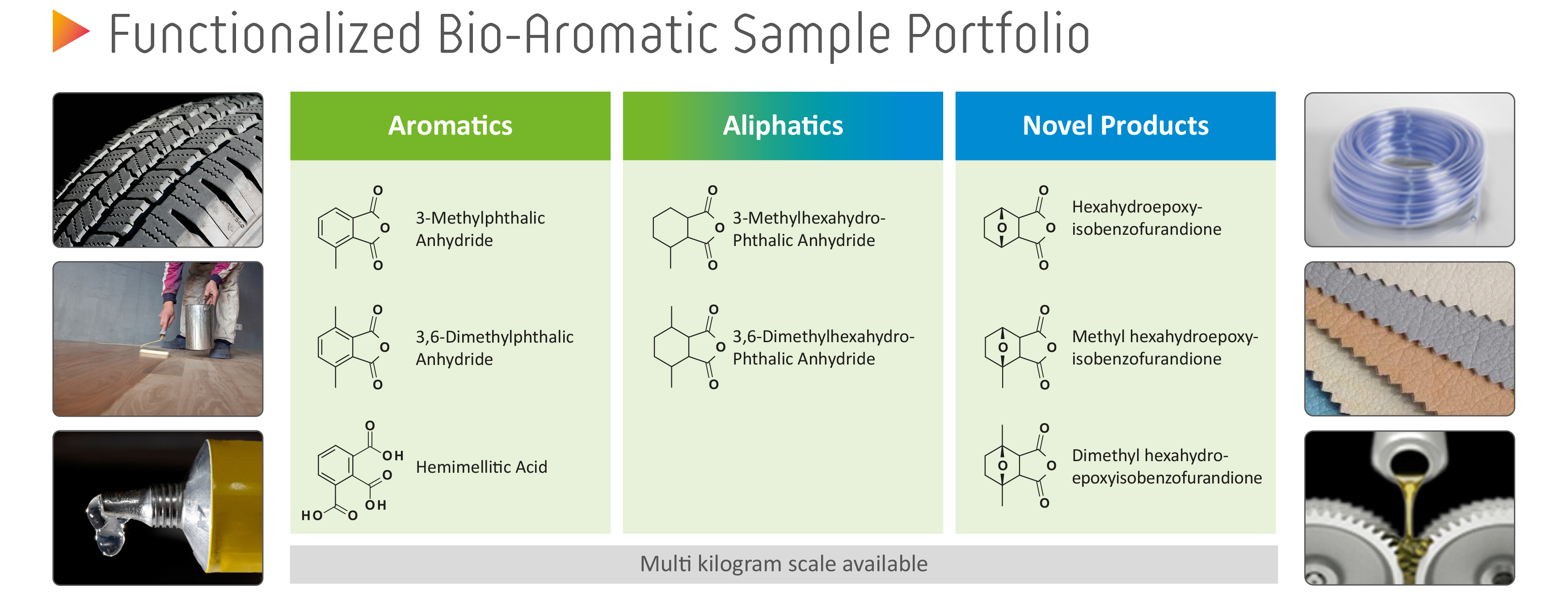

Biorizon co-initiator TNO has made considerable progress in scaling-up the production of functionalized biobased aromatics via Diels-Alder technology starting from furans. This has resulted in a unique portfolio of various samples that bring premium properties such as durability, stability, and high temperature performance to products such as coatings, adhesives, sealants, elastomers, engineering plastics and polyurethane. We invite you to test these samples in your applications and share your experience with us.

Biorizon: The Profitable Way to Bio-Aromatics

Since 2013, at the Green Chemistry Campus in Bergen op Zoom, Biorizon Shared Research Center has been co-creating technologies for the commercial production of bio-aromatics. Biorizon, an initiative of TNO and VITO, wants to enable commercial production of bio-aromatics by 2025. To accomplish this, Biorizon focuses on scaling up technology to pave the way for industrial-scale production with continuous processing. Biorizon co-initiator TNO is currently validating the continuous Diels-Alder processes and working with industry partners toward the next stage: facilitating commercial implementation. This will result in bio-aromatic building blocks that afford better properties in applications, and are renewable, competitive and safe, and reduce significantly CO2 emissions, which is needed to combat climate change.

Scaling-up Technology for the Production of Samples

At Biorizon’s headquarters at the Green Chemistry Campus in Bergen op Zoom, TNO has invested considerably in the scaling-up of conversion technologies, starting from furfural made from hemicellulose for the production of various samples. Despite COVID-19, the last couple of months, we have worked hard to enable the production of more than 40 kilograms samples (see structures above), e.g.:

- Aromatic tri-acids (HMA)

- Phthalic anhydrides (3-MPA & 3,6-DMPA)

- Hexahydrophthalic anhydrides (3-MHHPA)

- Oxabicycloheptane dicarboxylic anhydrides (H2-F/MA, H2-MF/MA, H2-DMF/MA).

These molecules can bring premium properties such as increased durability, improved stability, and better high temperature performance to products such as coatings, adhesives, sealants, elastomers, engineering plastics and polyurethane. TNO has developed unique methods to remove specific impurities, which has resulted in highly pure (>99%) samples. Currently, TNO further invests in dedicated analysis equipment at the Green Chemistry Campus to further improve the understanding of the process.

Test Highly Functional Bio-Aromatics Samples in Applications

To be able to reach Biorizon’s ultimate goal – enable the commercial production of bio-aromatics – TNO invites companies that are willing to test our bio-aromatics samples in their applications. In return, we are keen to hear how our bio-aromatics perform in actual applications such as coatings, adhesives, sealants, elastomers, engineering plastics and polyurethane and thus, what added value they bring to manufacturers of these products.

Specifically, TNO participates in various projects and project proposals that combine technology development and evaluation by end-users. Furthermore, we have gained a vast experience in bilateral collaborations with companies where we evaluate the added value of our samples in specific applications. Due to non-disclosure agreements, we can’t specify company names, but a response we typically get is: “When commercially available, we will definitely use these bio-aromatic based resins”.

More information

Do you want to know more about testing highly functional bio-aromatic samples in your applications or about Biorizon in general? Monique Wekking, horizon manager ‘sugars to bio-aromatics’ is happy to talk you. You can contact her at monique.wekking@tno.nl or +31 (0)6 46 84 73 58.