News

26-06-2024

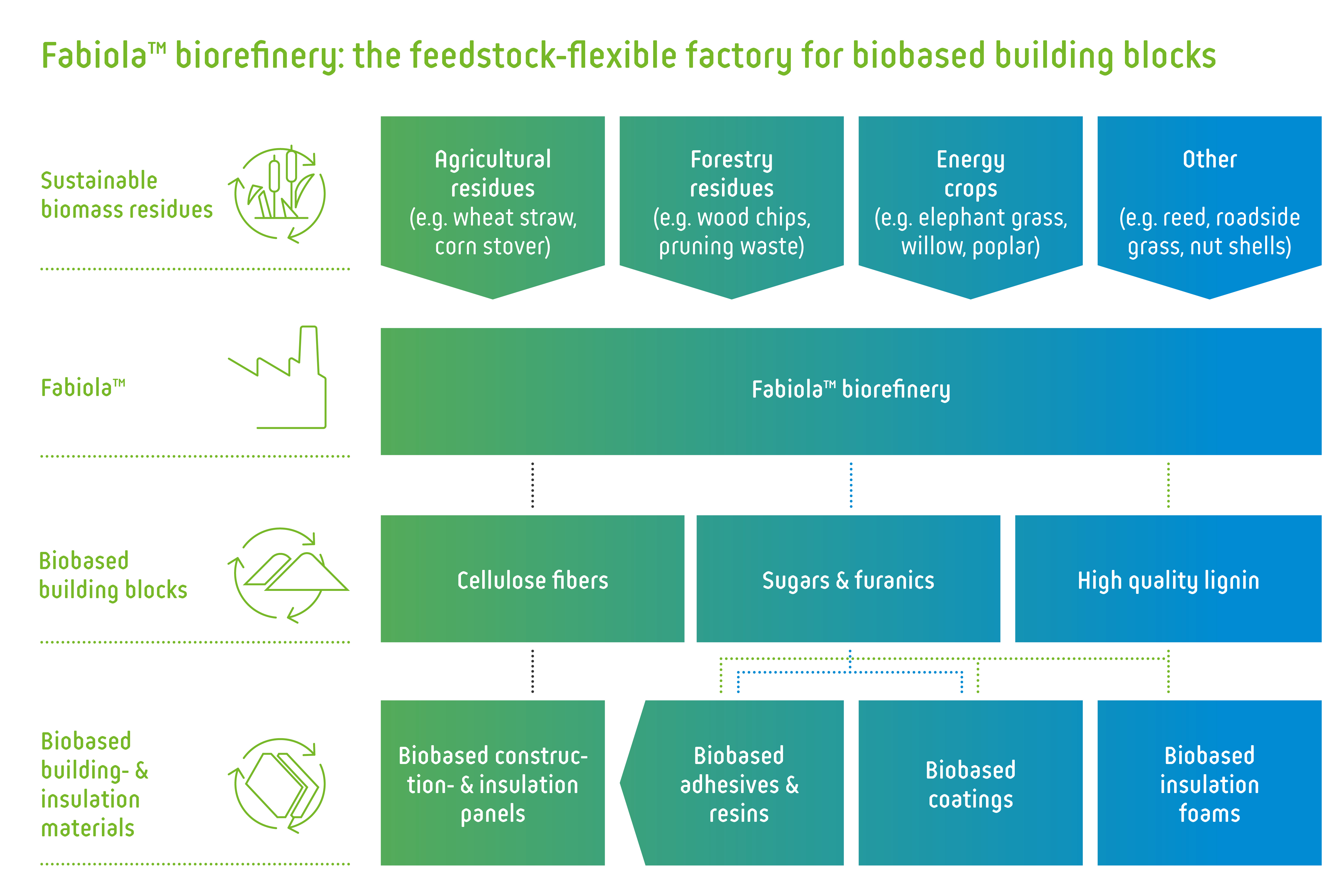

Fabiola™ biorefinery: the feedstock-flexible factory for biobased building blocks

Biorizon co-initiator TNO has created Fabiola™, a prototype of a next-generation biorefinery capable of processing a variety of biomass residues into cellulose fiber, sugars, furanics, and high-quality lignin. As a TNO Tech Transfer project, Fabiola is now available for scale-up to full demo scale, and the team is in search of more partners to help the entire biomass value chain take full advantage of this remarkable technology to attain their own sustainability, production, or manufacturing objectives.

Replacing fossil-based products with sustainable biomass residues is one of the keys to a sustainable future. Besides reducing our environmental impact, it may also reduce geostrategic dependencies on fossil resources. Biorizon co-initiator TNO has developed a Next-generation Biorefinery process with the flexibility to turn a wide variety of biomass into high-quality building blocks for an even wider variety of applications.

The road to net zero

Although many countries have set ambitious targets to reduce emissions by 2030 and eliminate them by 2050, progress in many areas has been slow. Among them are biorefinery solutions that enable industries to make full use of biomass to replace the core components of fossil-based products, from building materials to coatings and insulation materials, and from adhesives to batteries and cosmetics. In this area, both legislative pressure and effective infrastructure are lagging behind. TNO aims to accelerate progress in this area by offering technology and expertise that reaches beyond what is currently possible.

Addressing the roadblocks

Building blocks extracted from biomass not only offer a viable alternative to fossil-based feedstock, but in many cases also outperform their fossil counterparts and require less energy and resources to produce. Unfortunately, the infrastructure is not yet in place to take full advantage of these valuable and sustainable resources. Current technology is not flexible or affordable enough to produce the needed quantities of each building block, and supply chains have not been optimised to accommodate the demand for biomaterials. TNO’s solution aims to solve several of these challenges. In addition, the solution can reduce strategic dependencies and offer viable alternatives to depleting supplies of fossil-based feedstock.

The TNO impact

TNO has created FabiolaTM, a prototype of a next-generation biorefinery capable of processing a variety of biomass residues – clean wood chips, agricultural and forestry residues, food processing residues, biomass from roadside verges and more – into cellulose fiber, sugars, furanics, and high-quality lignin. This flexibility is essential for shortening supply chains, reducing operating costs, and maximising up-scale capabilities.

As a TNO Tech Transfer project, Fabiola is now available for scale-up to full demo scale, and the team is in search of more partners to help the entire biomass value chain take full advantage of this remarkable technology to attain their own sustainability, production, or manufacturing objectives.

Quality as a key objective

Along with a flexible and cost-effective solution for biorefining, Fabiola addresses a key challenge that other refineries cannot. Namely, the production of high-quality lignin that can be used to develop polyurethane foams, resins, coatings, and adhesives. The Fabiola system is able to extract 75-80% of high-quality lignin from biomass, which can drive the biobased value chain toward more and better uses for this highly valuable building block.

In addition, Fabiola can yield 90-95% of cellulose fibers from feedstock, ideal for applications like construction and insulation panels and food packaging, with future applications for textiles, composites, plastics, and platform chemicals. Fabiola has also demonstrated 80-95% yields of sugars and furanics that form the basis for biodegradable plastics, adhesives, and common chemical building blocks. The highly efficient biorefinery has already demonstrated an ability to convert 80-90% of biomass into useable components. The demo-scale biorefinery will not only address any scaling issues, but will further optimise the refining process, together with stakeholders.

Expertise at work

TNO is also working with partners to accelerate the materials transition and achieve climate, strategic, and production goals in other ways. Through our partnership in Biorizon Shared Research Center, TNO works with VITO on the most advanced and renowned research programme for bio-aromatics. Under the flag of Biorizon, TNO is promoting and expanding the Fabiola solution to usher the entire biobased value chain into a new era of development and solutions to key challenges in this domain.

Achieving ambitious climate goals will require a number of interconnected solutions that work together to reduce our carbon footprint. Interested in helping to enable the first flexible, cost-effective Next-generation Biorefinery in the world? Want to learn more about how to participate, revolutionise your biobased materials production processes, and reduce your carbon footprint?

Please contact Biorizon's Thermochemical Horizon Manager Arjan Smit at arjan.smit@tno.nl or +31 (0)6 50 00 96 12.