News

03-12-2020

7th Biorizon Annual Event on Bio-Aromatics: Webinar on Demand

A record number of more than 300 participants from 29 nationalities, a live webinar broadcast, 3 breakout sessions and numerous matchmaking sessions. Our 7th Annual Event on Bio-Aromatics - and our first virtual edition - was well-received. For those of you who want to (re)watch the webinar, our animation video or the three horizon movies that show our facilities, we've included these below. We sincerely hope next year we will be able to meet you in person and raise glasses. In the meantime we invite you to join our community.

Biorizon's Annual Event - Webinar on Demand

Get informed about the latest progress in the field of biobased aromatics! In this interactive webinar Katharina Andrés, Senior Business Development Manager Energy Transition TNO, is your host.

- Biorizon's director Joop Groen shows you the progress that Biorizon Shared Research Center has made in the scaling up of the production of bio-aromatics with premium properties.

- Short movies and an animation will give you an impression of Biorizon's facilities, the samples that we have available and the opportunities for the industry to participate.

- Wilfried Blokzijl, R&D director Homecare at Unilever Europe delivers a keynote speech about Unilever's Clean Future program.

Biorizon Shared Research Center: Animation Video

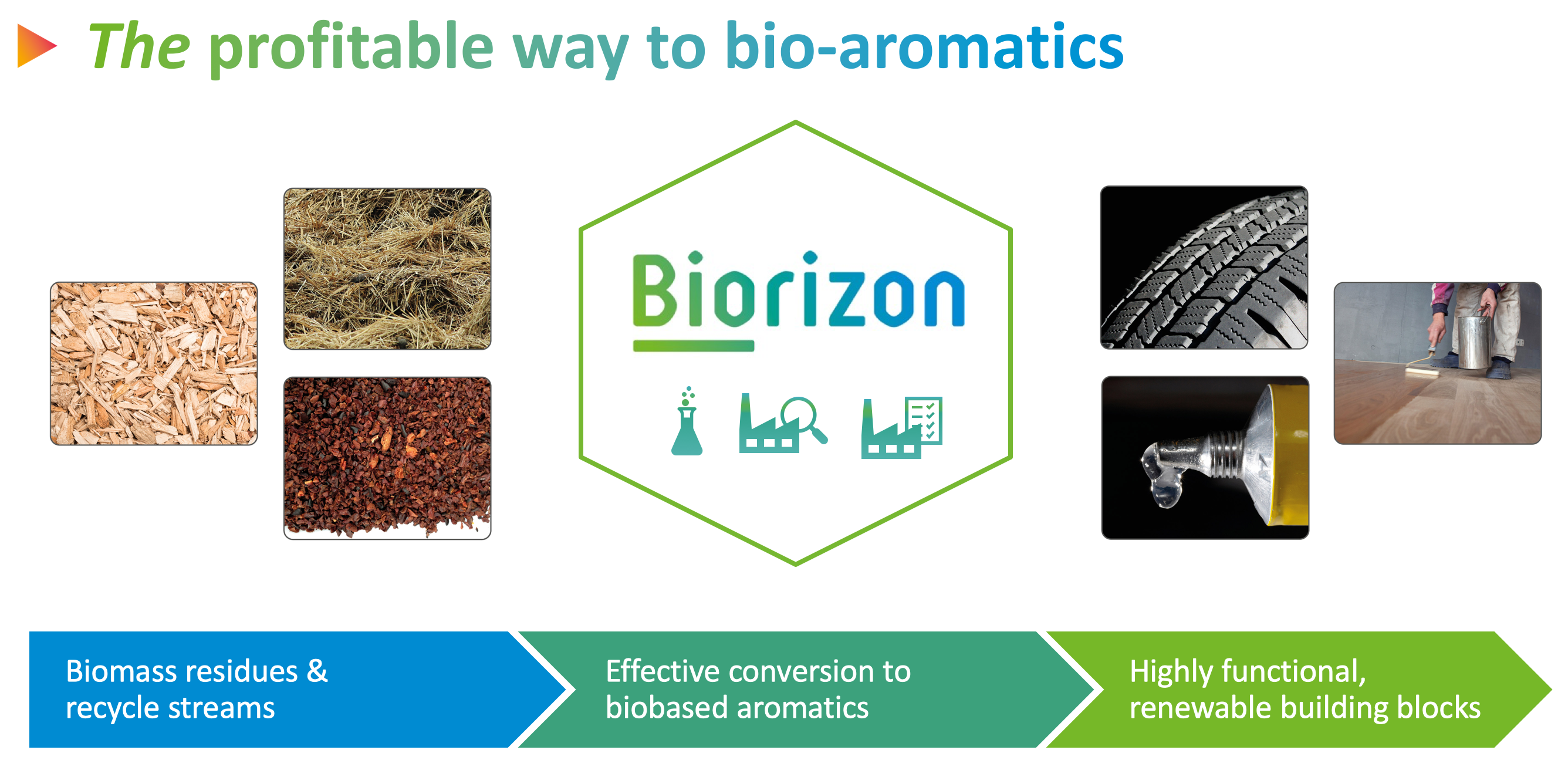

"We all know these everyday products created by our industry and big consumer brands. Their production relies on an essential class of building blocks called 'aromatics.' Right now, these aromatics are petrochemical-based. But because of climate change and the exhaustion of natural resources, we know our industry is in desperate need of sustainable alternatives, preferably from local sources and with premium properties."

"Biorizon Shared Research Center believes a circular bio-economy is the solution. In cooperation with the industry, we develop state-of-the-art technologies to produce bio-aromatics from plant-based side- and recycle streams. These renewable aromatics outperform their fossil counterparts in sustainability as well as functionality. They give our industrial partners the essential functionalities they need. Such as durability and thermal and UV stability to products like plastics, resins, and coatings. And even better: bio-aromatics provide an impactful and green alternative for difficult to re-use and recycle products like paints, adhesives, or lubricants."

"Biorizon’s key objective is to enable the commercial production of bio-aromatics by 2025. To accomplish this, we continue scaling up our technologies and offer samples that companies can test in actual industrial applications. Our bio-aromatics research center is unique in the world. We offer you an excellent collaboration platform to make the transition to a circular bio-economy. Please join our active community, and together with international partners from the entire bio-aromatics value chain, we create a profitable and sustainable future. Join us at biorizon.eu/community."

Biorizon's Thermochemical Horizon

"Biorizon Shared Research Center focuses on scaling up bio-aromatics technology. Here, at the Green Chemistry Campus in Bergen op Zoom, Biorizon co-initiator TNO is piloting a new technology; thermochemical depolymerization of lignin and lignin-rich biomass. Via pyrolysis and closely-coupled staged condensation, the feedstock is split into bio-aromatic rich oil fractions and char. This allows higher-added-value application, and a combustible gas for process heat."

"In Petten, we have our biofuels and biochemicals lab. Here, TNO focuses on the co-production of BTX – benzene, toluene and xylenes, in biomass gasification. The technology enables the selective extraction of BTX as a valuable intermediate for the chemical industry. We can convert Ethylene to BTX and co-extract it to increase the BTX yield. This technology is used as part of gasification-based biorefinery concepts for biofuels and biochemicals production."

"For both technologies we also explore the potential for chemical recycling of plastics. TNO is able to produce representative 1-10 kg-scale samples for application development, in close cooperation with the industry. For BTX, we target bulk applications like plastics, but also niche applications like fragrances. For bio-aromatic rich oil fractions, we target bitumen, resins, coatings and fuel additives."

Do you want to cooperate to bring these technologies to market? Or do you want to test samples in yoúr application? Please contact Biorizon's Thermochemical Horizon Manager Jaap Kiel at jaap.kiel@tno.nl or +31 (0) 6 26 43 49 26 and join our community.

Biorizon's Sugar Horizon

"Biorizon Shared Research Center Biorizon wants to enable commercial production of bio-aromatics by 2025. Let’s go inside and I’ll show you what we do!"

"Since 2013, Biorizon co-initiator TNO has created an unique IP-portfolio position for the production of functionalised bio-aromatic monomers, starting from commercially available bio-based furfural. Our initial focus is on specialty bio-aromatics which display improved properties in end products. That can be, for example, increased physical durability or improved UV-stability. We are targeting applications in which recycling of the current petrochemical products is seen as being too challenging, such as coatings. In these areas, we see biobased components as the best solution to realize a sustainable future."

"At our pilot facilities here at the Green Chemistry Campus in Bergen op Zoom, TNO is capable of producing various bio-aromatic samples up to 10s of kilogram-scale, such as hemimellitic acid, 3-methylpthalic anhydride and 3-methylhexahydrophthalic anhydride. TNO has established spinoff company Relement that will take the next step towards commercialization. Our Diels-Alder Platform technology allows TNO to expand the portfolio to other specialties or bulk aromatics, depending on specific industrial requests."

"We invite you to change the future of the chemical industry by testing our samples in your product and find out the benefits yourself. Are you with us?"

Do you want to know more about testing highly functional bio-aromatic samples in your applications? Please contact Biorizon's Sugar Horizon Manager Monique Wekking at monique.wekking@tno.nl or +31 (0)6 46 84 73 58 and join our community.

Biorizon's Lignin Horizon

"Biorizon Shared Research Center believes that a circular bio-economy is the solution to the challenges of the chemical industry. Here, at the lab facilities in Mol, in Flanders, Biorizon co-initiator VITO is working on the scaling up of the production of lignin-based bio-aromatics. Why lignin? Because it is the second most abundant renewable carbon source on earth."

"In this lab, VITO develops and matures technology for the depolymerization and fractionation of lignin-rich biomass into bio-aromatics. We target aromatics with new functionalities that lead to improved product properties. The technology we use, results in different lignins, ranging from monomeric to oligomeric mixtures. A variety of bio-aromatics can be obtained by matching the appropriate starting materials and depolymerization technology."

"VITO is now scaling up a unique conversion technology to produce lignin-based building blocks for the fine chemical industry and innovative biorefineries. We started the engineering and construction of a continuous lignin depolymerization pilot plant, called LignoValue. This plant will produce renewable bio-aromatics that can be used in different high added-value applications, such as polymers, adhesives and composites."

Right now, several companies are already testing samples of bio-aromatics in actual applications. Do you want to join this transition to bio-aromatics that are sustainable, profitable ánd highly functional? Please contact Biorizon's Lignin Horizon Manager Karolien Vanbroekhoven at karolien.vanbroekhoven@vito.be or +32 (0)4 93 51 42 70 and join our community.

Event presentations in community library

All event presentations are exclusively available for Biorizon community members in our community library. Subscribe now, it only takes a minute and is free of charge.