Facilities

Shared Research Center Biorizon has state-of-the-art facilities at its disposal. The facilities can be found at the following locations:

VITO in Mol

Differential Scanning Calorimetry (DSC)

DSC measures temperatures and heat flows associated with thermal transitions in a material.

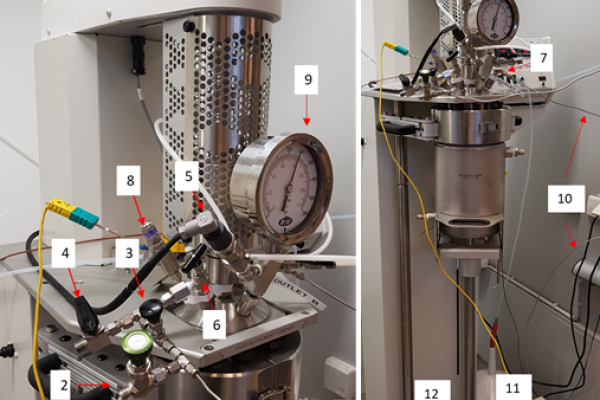

VITO in Mol

Small scale reactor set

This small scale reactor set with mechanical overhead stirrer allows to perform viscous reactions which cannot be performed using a magnetic stirring bar. This set-up allows closed reactions in vacuum and in inert atmosphere.

Green Chemistry Campus, Bergen op Zoom

PYRENA-PYPO: Continuous Pyrolysis Pilot for Biobased Additives & Aromatics

The PYRENA-PYPO equipment is a continuous pyrolysis pilot unit consisting of a 5-10 kg/h (input basis) pyrolyzer, known as PYRENA, with a closely coupled unit, known as PYPO, for fractionated recovery of the pyrolysis vapours.

Green Chemistry Campus in Bergen op Zoom

Continuous Hydrogenation Skid

This skid will enable conversion of the products of the Continuous Biphasic Reactor Skid into the production of several furanic feedstocks for Continuous Flow Diels-Alder Skid, as well as several pseudo-aromatic products (such as hexahydrophthalic anhydride derivates) on the multi-hundreds to kilogram per day scale (skid throughput of 0.1-1kg/hr. This skid will be delivered in Q1 2020.

Green Chemistry Campus in Bergen op Zoom

Batch Vacuum Distillation Unit

This unit will enable both solvent and reagent recovery and recycling, as well as being suitable for the purification of the bio(pseudo)aromatic products.

TNO in Delft

1L/3.75L Batch Autoclaves

These units allow for the production of a range of products on the hundred gram-scale in processes which require high-pressure processing. This allows for the production of samples for application testing while continuous skids are designed and constructed for the specific steps.